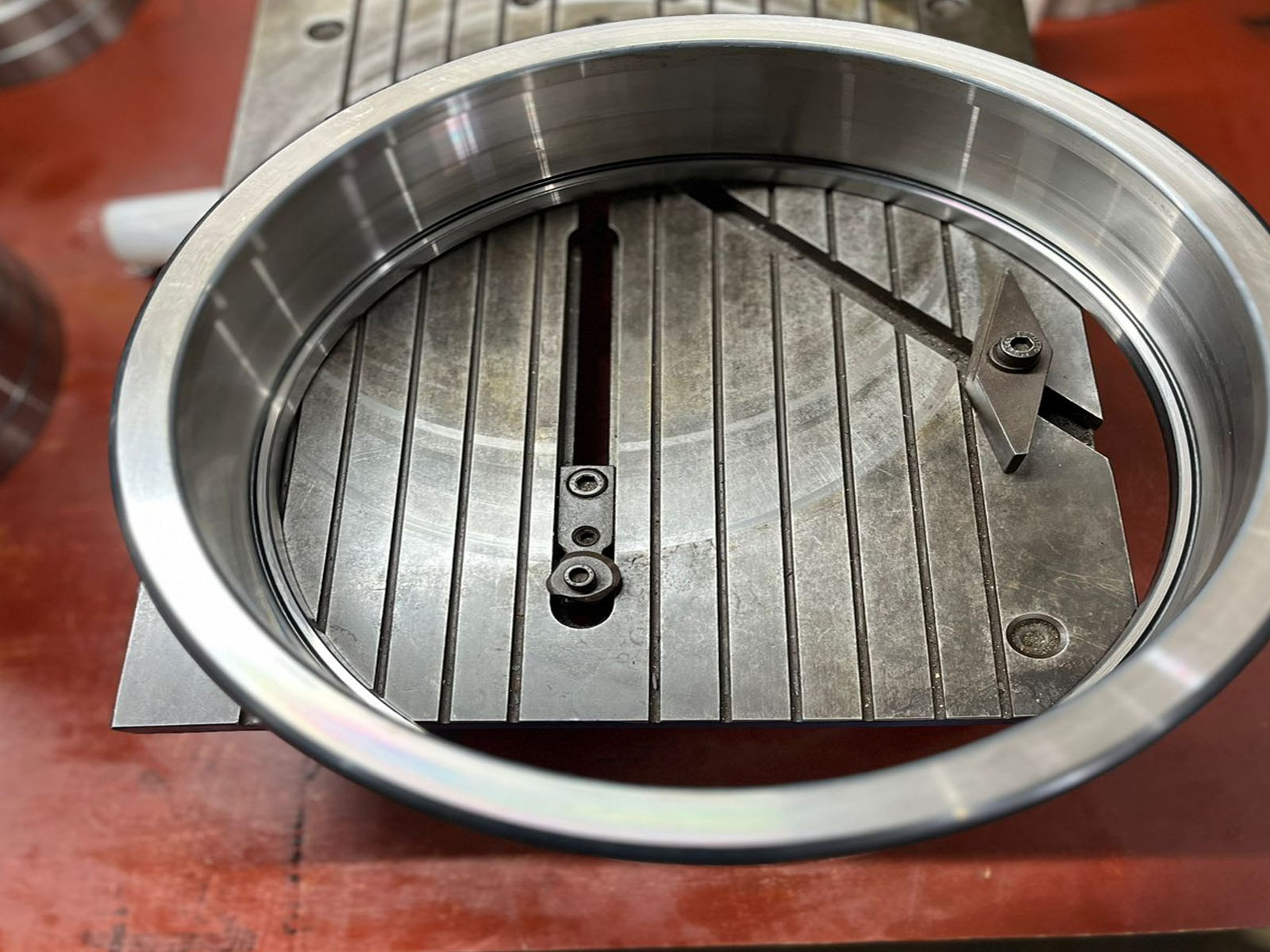

Bearing Component

Bearing Component

A bearing is a machine element that constrains relative motion to only the desired motion, and reduces friction between moving parts. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis; or, it may prevent a motion by controlling the vectors of normal forces that bear on the moving parts. Most bearings facilitate the desired motion by minimizing friction. Bearings are classified broadly according to the type of operation, the motions allowed, or to the directions of the loads (forces) applied to the parts.

Rotary bearings hold rotating components such as shafts or axles within mechanical systems, and transfer axial and radial loads from the source of the load to the structure supporting it. The simplest form of bearing, the plain bearing, consists of a shaft rotating in a hole. Lubrication is used to reduce friction. Lubricants come in different forms, including liquids, solids, and gases. The choice of lubricant depends on the specific application, and factors such as temperature, load, and speed. In the ball bearing and roller bearing, to reduce sliding friction, rolling elements such as rollers or balls with a circular cross-section are located between the races or journals of the bearing assembly. A wide variety of bearing designs exists to allow the demands of the application to be correctly met for maximum efficiency, reliability, durability and performance.

Commited to High Quality Service

The Company has been founded by Mohit and his family members. Mr. Mohit is a well-known industrialist from Jaipur City.

Types of Bearing

Plain bearing

Rubbing surfaces, usually with lubricant; some bearings use pumped lubrication and behave similarly to fluid bearings.

Rolling element bearing

Ball or rollers contact both rotating and stationary surfaces which rotate rather than rub

Jewel Bearing

Off-center bearing rolls in seating.

Fluid bearing

Fluid is forced between two faces and held in by edge seal.

Magnetic Bearing

Faces of bearing are kept separate by magnets.

Flexure Bearing

Material flexes to give and constrain movement.

Composite Bearing

Plain bearing shape with PTFE liner on the interface between bearing and shaft with a laminated metal backing. PTFE acts as a lubricant.